- HOME PAGE

- CORPORATE

- PRODUCTS

- Adiabatic Dry Cooler

- DRY Coolers H/V/W and Vertical Types

- Cooling Towers

- Chillers

- Commercial Air Cooled Condensers and Konbox

- HT-LT Type Dry Cooler

- Standard Cold Room Evaporators

- Industrial Air Cooled Condensers

- Oem Heat Exchangers Copper/Aluminum/Stainless Steel

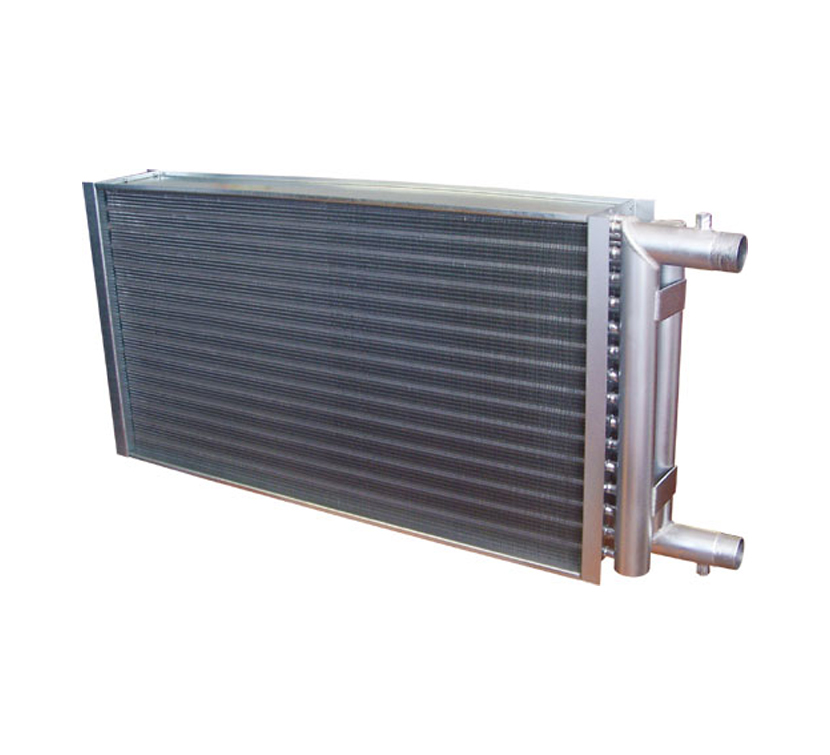

- Air Heating Coil Units

- Radiator- Exchanger Group

- PRODUCT SELECTION PROGRAM

- MEDIA

- CAREER

- CONTACT

- HOME PAGE

- CORPORATE

- PRODUCTS

- Adiabatic Dry Cooler

- DRY Coolers H/V/W and Vertical Types

- Cooling Towers

- Chillers

- Commercial Air Cooled Condensers and Konbox

- HT-LT Type Dry Cooler

- Standard Cold Room Evaporators

- Industrial Air Cooled Condensers

- Oem Heat Exchangers Copper/Aluminum/Stainless Steel

- Air Heating Coil Units

- Radiator- Exchanger Group

- PRODUCT SELECTION PROGRAM

- MEDIA

- CAREER

- CONTACT

Size Nasıl Yardımcı Olabiliriz

Catalogue

Catalogue

BACK TO TOP

BACK TO TOP