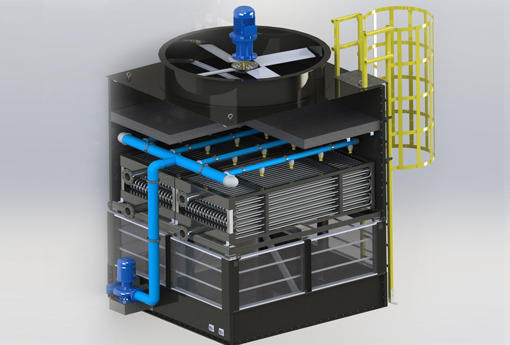

The coolant used in the process is introduced to the heat exchanger via pipes made from galvanised, stainless steel or copper, located in the closed type cooling tower. This allows the excess heat to be removed. The water sprayed on the heat exchanger pipes and the air drawn from the external environment with the help of the fan facilitate the cooling of the process fluid, which then leaves the heat exchanger. Our closed cycle cooling towers provide a highly efficient cooling solution by completely isolating the process coolant from the atmosphere.

The absence of contact between the process coolant and the air in closed-cycle cooling towers prevents contaminants from entering the system, thereby safeguarding the quality of the fluid and reducing maintenance costs due to contamination. By preventing pollution in closed-type cooling towers, we can ensure that the product demonstrates 100% thermal performance throughout its life, while minimising system operating costs.

Hybrid cooling towers are utilised in instances where high-efficiency process cooling is required, offering optimal water savings and preventing fog formation. Hybrid cooling towers comprise a finned tube dry coil and a finless tube wet heat exchanger. The process fluid is first directed into the finned tube dry coil, which is situated at the top of the tower. The process fluid is discharged from this coil with the help of fans, which allow some of the excess heat to dissipate into the atmosphere. Subsequently, the process fluid enters the heat exchanger with finless tubes. The process fluid is cooled to the desired temperature with the help of water sprayed on the heat exchanger and fans, and then leaves the hybrid closed-cycle cooling tower. The hybrid closed-cycle cooling tower is the preferred option in processes where water costs are high, water supply is problematic, fog formation is not desired or when high-temperature fluids need to be cooled.

The hot coolant from the process first enters the water distribution system located in the open cooling tower. Thanks to the sprinklers in the water distribution system, it is sprayed in droplets onto the material acting as a heat exchanger, called the filler. The filling material is made of PVC or PP materials. The function of the fill material in the open type cooling tower is to create a heat transfer surface between the process fluid and the atmospheric air drawn in by the fan. The hot process fluid cools and collects in the basin at the bottom of the open circuit cooling tower. The heated outdoor air is discharged to the atmosphere by a fan.

THE ONLY COMPANY IN TURKEY:

Konuk Isı is the only company that manufactures open circuit cooling towers in its own factory using both GRP and sheet metal materials.

HIGH EFFICIENCY PERFORMANCE:

Open type cooling towers can cool the refrigerant to values close to the wet bulb temperature of the air, no matter how high the dry air temperature is.

LOW INITIAL INVESTMENT COST:

Due to the use of very high efficiency packing materials, the initial investment cost of the open type cooling tower is very low.

EASY INSTALLATION - QUICK ASSEMBLY:

As all products are factory assembled, the open circuit cooling tower consists of two or three parts. These parts can be placed on top of each other at the installation site and the installation can be completed very easily and quickly.

7/24 SERVICE AND MAINTENANCE:

With its advanced staff and service network, our company can provide 24/7 service and maintenance.

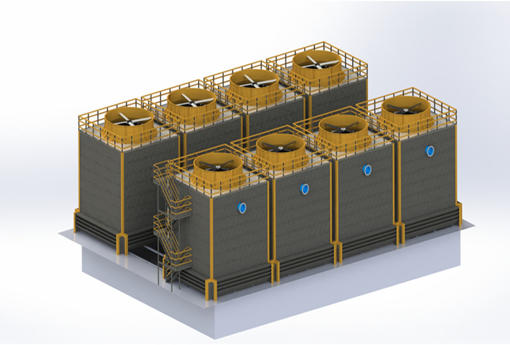

GRP counter flow cooling towers are used in all sectors such as energy, iron and steel, food as well as in all industries.

GRP counter flow cooling towers are the most preferred type of counter flow cooling towers in recent years. The main advantage of GRP cooling towers is that they are resistant to the destructive effects of water, air and sun. There is no risk of corrosion.

Advantages of pultrusion ctp structural elements used in cooling towers

High strength

Pultrusion GRP profiles approach the strength of steel in tension and compression.

Light weight

80% less than steel, 30% less than aluminium.

Corrosion resistance

` Unaffected by a wide range of abrasive materials; resistant to deterioration.

Quality construction

Cut and drilled to project specifications, GRP profiles do not warp, bend or split after manufacture. This ensures safe and efficient installation of the tower on site.

Non-conductive

Reduces the risk of electric shock compared to metal towers.

No protective maintenance chemicals are used in the cooling tower structure.

Flame retardant products are available on request.

Kontherm offers turnkey cooling tower and pumping station design, project engineering and installation services with a dedicated engineering staff and experienced technical team.

Our solutions, which are specifically designed to meet the needs of our customers, utilise innovative technologies aimed at increasing energy efficiency and reducing operating costs. We ensure high performance, long life and minimum maintenance costs in your projects by providing reliable service across a wide range of industrial plants to infrastructure projects.

If you are looking for comprehensive engineering support for your projects, discover Konuk Isı`s professional solutions and contact us for detailed information about our customised solutions.